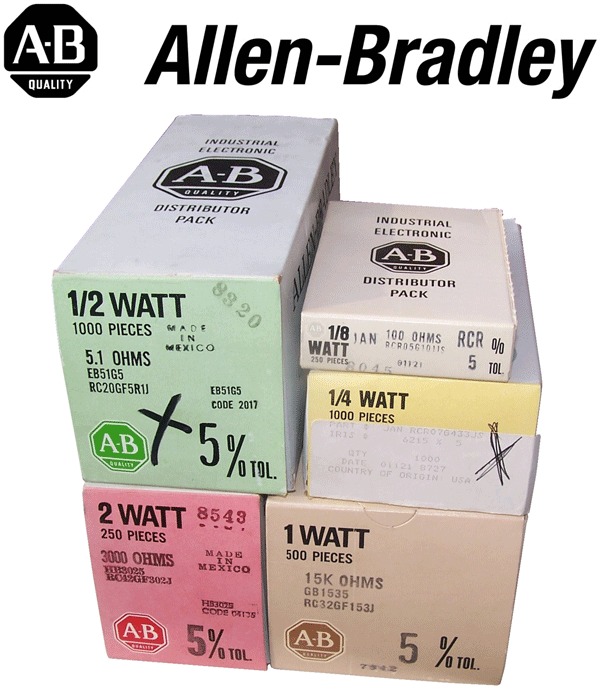

Allen Bradley Resistors

We have huge stocks of the full range of Allen Bradley resistors. So hificollective is proud to offer you a broad range of values of 0.125 watts, 0.25 watts, 0.5 watts, 1 watts and 2 watts.

For many many years, these carbon composite resistors from the States have been held in high regard for hi-fi and for guitar amp use. Their natural organic tone is truly sublime. Unfortunately, production stopped in the 1990s and ever since then the stocks have been diminishing fast.

These "hot-moulded carbon" resistors offer the simplest of concepts for a resistor design. They effectively consist of a solid cylindrical carbon resistive element with leads embedded at each end. Making them incredibly rugged and highly reliable, together with their non-magnetic and non-inductive characteristics, these little gems are remarkable in performance and sound.

If you pay close attention to the "Explanation of Part Numbers" diagram below, you will see that there are various parts numbers employed for these resistors - engineers love their part numbers!. Firstly we have the Allen Bradley code (industrial type designation), consisting of 6 digits. This is what we use as the basis for our coding. The 0.125-watt codes start with BB, The 0.25-watt with CB, The 0.5-watt with EB, the 1-watt with GB and the 2 watts with HB. These have their equivalent Military type designation that starts with RC, and then you have the Military Grade-S designation that starts with RCR. These are the creme de la creme of the Allen Bradleys; pls note we have ended our part number with R to denote this type. You also need to know that they have two resistive tolerances, 5% and 10%.

Please note that these are NOS resistors, and the actual true tolerances will be slightly more - please read the "special treatment" paragraph below on this.

Follow this sequence when purchasing if you have a choice. The best resistors are at the top of the list. The RCR code is denoted by an "R" at the end of the FIRST SKU. For example, HB1805R is an RCR, Military-grade version.

- HB1805R: 18R 2W Allen Bradley 5%, RC42GF180J, RCR42G180JS - MILITARY GRADE

- HB1805: 18R 2W Allen Bradley 5%, RC42GF180J, RCR42G180J* - NON MILITARY GRADE

- HB1801R: 18R 2W Allen Bradley 10%, RC42GF180K, RCR42G180KS - MILITARY GRADE

- HB1801: 18R 2W Allen Bradley 10%, RC42GF180K, RCR42G180K* - NON MILITARY GRADE

PRICE 1 off

0.125W - £0.27+vat+p&p

0.25W - £0.32+vat+p&p

0.5W - £0.37+vat+p&p

1W - £0.90+vat+p&p

2W - £1.48+vat+p&p

SIZES

0.125W - body: 1.5mm diameter x 3.8mm length. Leadouts: 0.36mm diameter x 25mm length

0.25W - body: 2.3mm diameter x 6.35mm length. Leadouts: 0.6mm diameter x 35mm length

0.5W - body: 3.5mm diameter x 10mm length. Leadouts: 0.8mm diameter x 35mm length

1W - body: 6mm diameter x 15mm length. Leadouts: 1mm diameter x 35mm length

2W - body: 8mm diameter x 18mm length. Leadouts: 1.15mm diameter x 35mm length

If you are looking for a specific value, we have added a RESISTOR FILTER to speed your search up.

Allen Bradley RESISTORS special treatment method

As stated, Allen Bradley resistors are carbon composite. Being made of organic material, they do have the tendency to absorb water from the atmosphere. This absorption can increase the actual resistance of the component, hence the slightly higher-than-normal tolerance published on this page. To fix this, remove the water from the component and seal it. The best method is to place the resistor/s on a baking tray, set your oven to 80 degrees centigrade and leave it in the oven for 8 hours. The secret is to remove the moisture slowly. If you rush, it will become noisy in the circuit. Once cooked, seal the body of the component in Shellack (preferably the flakes) to stop further water absorption. At the end of this procedure, you will have much lower noise and more closely tolerant resistors. Special thanks to Colin Cornish for this excellent tip.